Excessive noise is one of the most common workplace hazards in industrial facilities. Prolonged exposure to noise in manufacturing industries can result in compromised verbal communication, fatigue, lower productivity and work-related hearing loss. Manufacturing areas are not the only places where noise can be hazardous and counterproductive.

Offices that share walls with factories or are subjected to outside noise from highways or airports face similar noise problems. In such environments, uncontrolled sound can interfere with the intended purpose of the space, resulting in hampered interpersonal communication, headaches and other problems.

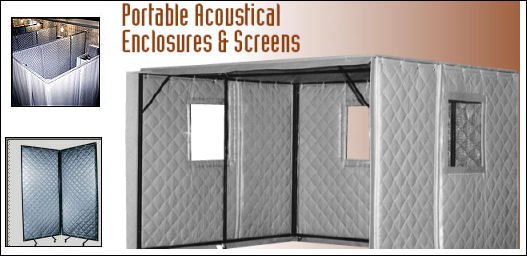

We Manufacture flexible and rigid Noise enclosure systems. Sound Curtains or Acoustic Blankets are flexible and can either be used independently or as part of an enclosure system. Custom-configured noise control enclosures are effective and economical method of noise reduction. Options include rooftop panels, grommets, view windows, sliding hinged and overhead doors, silencers, exhaust fans and more.

Noise Reduction Coefficient (NRC) is the average of the absorption coefficients at the most common frequencies (250, 500, 1000 and 2000 Hz.) The NRC is often used to compare the acoustical performance of various materials. Sound Transmission Class (STC) is a measurement of how much noise is stopped by a barrier or enclosure. It is an approximation of how much noise, in decibels, will be stopped by the material, assuming an airtight seal around the noise source. Sabin is a unit of sound absorption based on one square foot of material. Baffles are frequently described as providing x number of sabins of absorption based on the size of the baffle tested, through the standard range of frequencies (125-4000 Hz.).

Excessive noise in industrial and manufacturing settings not only reduces productivity, it puts workers’ health at risk, exposure to loud noise causes stress and fatigue that can lead to workplace injuries, as well as hearing loss. Reducing noise levels in commercial offices can be achieved by utilizing a variety of materials. Wall and ceiling mounted acoustic panels, hanging baffles and high performance ceiling tiles are commonly utilized to improve speech intelligibility and sound quality within commercial office environments. Call centers, conference rooms and open floor plan office settings require different noise absorption surfaces to achieve acceptable sound levels.

Industrial noise control is complex by nature. All Noise Control will deliver a cost-effective well planned soundproofing and noise control solution.

Industrial Facility Managers often contact All Noise Control to lower their noise levels within their facilities. We manufactur high performance industrial noise control products and noise control systems that is sued to solve most common and complex noise control applications.

Our engineered noise control solutions provide noise control solutions for plant managers to solve their industrial noise control problems. Common noisy equipment such as Vacuums, industrial generators, blowers, vacuum pumps, stamping presses, air handling units and many others have been successfully treated with the below listed options.

Noise Control and Soundproofing Products Made in U.S.A

![]()

Unsure if you found your sound solution? Call us right away at 1-561-964-9360 or fill out our contact form here.

Noise Control Data Downloads:

Noise Control Blanket Enclosure Brochure

Noise Control Blanket enclosures offer high levels of noise control and noise reduction. From HVAC units to large computers, office equipment or generators. Pipes, electrical devices, generators or Vacuums, all can be enclosed and their noises isolated by custom enclosures which will quiet their surroundings and prevent other complicated noise issues from starting.

- Noise Control Blankets Framing Hardwarde

- Industrial Noise Control Noisy Equipment

- Industrial Generator Soundproofing

- Industrial Noise In-Plant Enclosures

Noise Control Blanket Enclosures for In Plant Application Brochure

The loudest & most abusive environments – Within the In-Plant market sites are constantly re-tooling machines, moving equipment, installing equipment. Worker safety and OSHA regulations are key. In-Plant facilities require flexible and durable materials for the huge variety of applications and noise control needs they come across day to day.

- Industrial In-Plant Noise Control

- Assembly Instructions Suspended Walls all areas

- Assembly Instructions Suspended Enclosure

- Assembly Instructions Ceiling Mounted Enclosure

- Assembly Instructions Floor Mounted Enclosure

- Assembly Instructions Roof Support

- Assembly Instructions Heavy Duty Hardware

- Assembly Instructions Attaching Heavy Duty Hardware

- Floor Mounted Track

- Floor Mounted Hardware – General Instalation

Outdoor Noise control Blankets Brochure

Industrial Noise Control Blankets effective way of noise reduction in machinery, pumps, Vacuums and anything that requires noise control. Noise Control blankets great solution for Industrial Noise Control. Read More about Noise Control Blankets

- Outdoor Noise Control Blankets

- Industrial Noise Control Products Catalog

- Industrial Noise Control Brochure

- Industrial Noise Control Blankets Presentation

- Exterior Grade Noise Control Brochure

In-Plant Portable Enclosures Brochure

In-Plant Enclosures are available in Complete or Partial enclosures. Enclosures can be floor mounted, ceiling mounted, wall mounted, or suspended from a roof deck. When using a complete four-sided enclosure with a roof, the noise reduction can exceed 20 dB(A) while still offering access, visibility and ventilation. Partial Enclosures are defined as a barrier wall, two or three sided enclosure, or a four sided enclosure without a roof. Noise reduction can exceed 15 dB(A) on a partial enclosure utilizing our Barrier Backed or Barrier Septum Composites. Standard components are utilized to offer custom enclosures to meet your specific application.

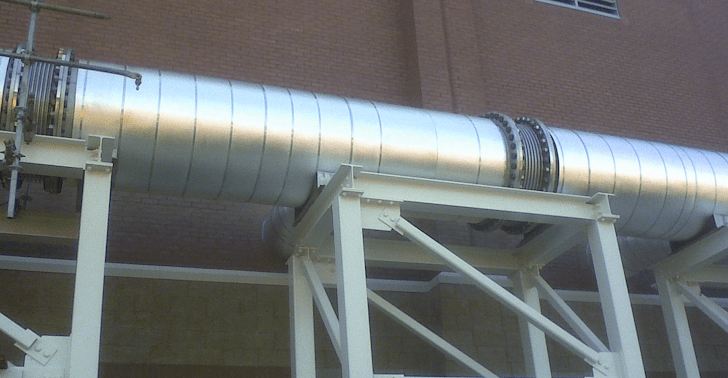

Industrial Acoustical Pipe and Duct Wraps Brochure

Industrial Noise Control Pipe & Duct Wraps are mass loaded noise control barriers with a reinforced foil facing on one side that allows for installation of matching lag tape. Pipe & Duct Wrap Lag is available with a 1″ or 2″ quilted fiberglass decoupler. Standard rolls are 54” wide x 30′ long. Typical used to wrap noisy pipes and ducts to block the noise that transmits through the walls of the pipe or duct as air or other contents move through it as well as to increase the sound absorption in the cavity. It also provides sound absorption and thermal insulation around the pipe or ductwork. The 2″ thick quilted fiberglass absorber improves low frequency acoustical performance. Use to wrap noisy pipes, ducts, valves, and fan housing.

Ideal for duct systems running over conference rooms, offices, and hospital rooms – Easily installed – 54” x 30′ rolls – Class A flammability