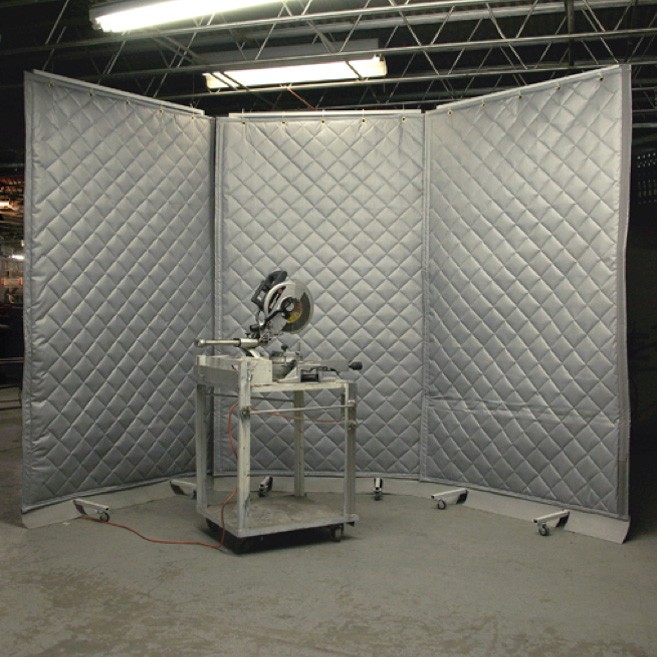

Soundproofing Blankets ANC-AB12 – Offering the benefits of both a noise barrier and a sound absorber in a single composite.

The barrier septum configuration offers the benefits of both sound absorption and noise barriers.

ANC-AB12 consists of a non-reinforced 1-lb psf loaded vinyl noise barrier sandwiched between two layers of vinyl-coated-fiberglass-cloth faced 1” quilted fiberglass sound absorbers.

- Curtain panels with grommets across the top and hook and loop fasteners along the vertical edges

- Rolls are available 4’ wide x 25’ long and can be supplied with edges bound or unbound

- Available colors: gray, white, black, or tan

- Class A (or 1) flammability rated per ASTM E84

The blankets come standard with grommets across one short side and mating Velcro along the vertical edges.

Mount these panels directly to a wall using self-taping screws and a washer. The self-tapping screws should be appropriate for the wall material and should be screwed through the washer and grommet into the wall.

The panels are designed to overlap adjoining panels by approximately 2″and be sealed in place with the Velcro along the panel edges.

The acoustical curtain panels have a natural corner strip for wrapping the panel system around a corner.

When the interior of a room is being lined butting the panels tightly in the corners of the room will suffice instead of the corner strip.