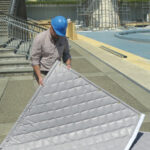

Foot Fall insulation system for free-floating type wood laminate and engineered wood floor.

Floating floors refer to installing an isolated floor from the framing or structure in order to reduce the resonant vibration energy within the wall or ceiling construction. By installing floating floors you are reducing structure borne or impact noise, such as footfalls, cupboards and doors shutting etc., that are being transmitted through a building’s structure. This type of floor soundproofing is referred to as STC (Sound Transmission Classifications) and IIC Ratings (Impact Isolation Ratings).