Vacuum are often noisy an effective solution is often required to suppress the noise emitted from them. Vacuum noise is usually a nuisance because they are sitting on comparatively lightweight structures. Noise levels in the assembly area did not exceed OSHA guidelines, management was concerned with worker moral and reductions in productivity. This case study report accounts the experience.

Noise Applications

Outdoor sound curtains are used to enclose outdoor chillers, Vacuums and hydraulic pumps. They serve as partitions for blower noise and outdoor fence construction. The panels also control noise from industrial projects like HVAC units. Factories, industrial sites, mining and manufacturing facilities commonly use them to comply with OSHA’s industrial safety noise levels.

Outdoor sound curtains reduce noise from chillers, generators, pumps, and equipment. The panels are flexible and can be installed on frames, fences, and other types of support. They are seen on the fences of construction sites, by-pass pumps, rooftop barriers, and gas Vacuums. The panels are modular and versatile. They are able to withstand prolonged UV exposure, high heat and are reusable.

The best way to Soundproof a Vacuum is to use our Sound Curtains Noise Barrier or Outdoor Sound Curtains that are an economical and effective method of reducing noise generated by equipment, pumps, generators or other processes that are outside and are exposed to the elements. This unique composite material combines a sound absorber with a noise barrier into a flexible and versatile panel.

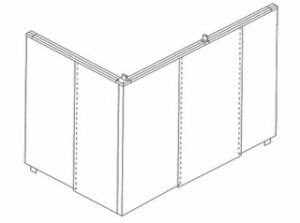

Sound Curtains panels are modular and can be installed on fences, frames, or other support structure. Applications are varied and include construction fencing, roof top barriers, by-pass pumps, gas Vacuums and many others.

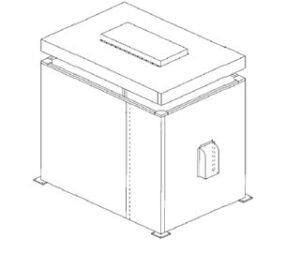

The best way to soundproof and to reduce any noise from a Vacuum regardless of size is to enclose it within a Floor Mounted 4-Sided Soundproofing Acoustic blanket Enclosure. For best results the enclosure should be as large as possible to allow less heat buildup and also to be more effective at reducing the noise output from reaching other areas and acoustically isolating the Vacuum to contain structure borne sound being transmitted from where it is mounted.

Depending on the current sound levels of the Vacuum and your noise reduction goals, an abatement solution can be determined. In most applications a soundproofing soundproofing blanket enclosure will meet your sound reduction needs. This is a two to four sided soundproofing enclosure with or without a roof. Typically a frame and track is constructed to suspend the soundproofing curtain panels. The soundproofing blankets material is a composite material bonding mass loaded vinyl with an acoustical absorber and faced with a vinyl diamond stitched facing.

Using our Soundproofing Acoustic Blankets to construct a 4-sided noise control solution will significantly reduce sound. The noise reduction to be expected is a range of 20 to 40 decibels. The better the construction, weight of blankets and amount of soundproofing acoustic blankets used (the surface area) all factor into your sound reduction numbers. Ensuring all corners and edges are tight and that there are no gaps is a major factor. The size of the blankets in which the amount of surface area that is available to dissipate and contain the noise is the other major factor.

Reducing noise by 20 to 40 decibels with this cost-effective, durable material is one of the best ways to solve noise control issues in commercial, facility & industrial markets

four-sided enclosure with roof and silenced ventilation

two-sided enclosure using sound curtain panels

|

OCTAVE BAND FREQUENCIES (Hz) |

|||||||

| Product | 125 | 250 | 500 | 1000 | 2000 | 4000 | STC |

| NC-25 | 12 | 16 | 27 | 40 | 44 | 43 | 29 |

|

OCTAVE BAND FREQUENCIES (Hz) |

|||||||

| Product | 125 | 250 | 500 | 1000 | 2000 | 4000 | NRC |

| NC-25 | .19 | .99 | .96 | .80 | .57 | .33 | .85 |

Noise Control USA providing a proven engineered solution for air Vacuum noise, with a sound curtain enclosure with sound curtain panels fabricated to meet your noise application needs.• Sound reduction of 12 – 18 dBA

• Silenced passive or forced air ventilation available

• Easy access to the equipment

• Enclosure easily installed and moved with equipment

• Class A (or 1) flammability rated per ASTM E84Noise Problem: An Air Vacuum located in a shop against a wall or in a corner, with continuous or discontinued motor or air Vacuum noise. Sound is reflected by the walls enclosing the Vacuum. Once the Vacuum cycles, the noise becomes unbearable to employees and customers in the shop.Noise Solution:Noise Control USA will provide an enclosure manufactured of NC-AB12 sound curtain panels surrounding the Vacuum. These enclosures are usually two, three or four sided with an open top.Depending on the case and demand we can provide you with a roof and ventilation system as well.

Applications

- Air Vacuum Noise Control Data

- Sound Curtains – Hanging Instalation

- Vacuum Sound Enclosure

- Sound Blanket Enclosure Installation

- Noise Control Presentation

- 4-Sided Sound Enclosure Sigle Track

- Outdoor Sound Blanket Short Term

- Acoustic Curtain Data Sheet

- Noise Barrier Blanket

- Air Vacuum Soundproofing Case Study

- Sound Curtians for Exterior Grade Noise

- Sound Blanket or Acoustic Blankets -AB Series Data

- High Temperature Acoustic blankets

- Acoustic Blanket Reinforced Exterior

- Outdoor Weatherproof Acoustic Blanket

- Sound Blanket & Curtain Hardware

Noise Problem:Noise bothering from the neighbor’s pool pump, generator, never ending construction or the noisy restaurant.Noise Control Solution:Noise control USA outdoor model (model#) sound curtains are an outdoor noise barrier that absorbs and blocks bothering sound. These curtains can be a temporary or even a permanent solutionMaterials for outdoor noise reduction include:

- Vinyl Sound Barrier

- Sound or Acoustic Blankets

- OEM products

Acoustic Blanket Non-Reinforced

NC-AB12 Noise Barrier/Sound Absorber Composite

NC-AB13 (1lb 3”) Noise Barrier

NC-AB22 (2lb 2″) Noise BarrierHigh Temperature Soundproofing Acoustic Blanket

AB12-HT High Temperature Noise BarrierOutdoor Soundproofing Weatherproof

AB1-110 Outdoor Short Term Sound Curtains

NC-AB1-112 Outdoor Short Term Sound CurtainsOutdoor Weatherproof Soundproofing

NC AB-220 Acoustic Quilted Fiberglass Absorbtion BlanketWeatherproof LongTerm Soundproofing Sound Curtains – non-reinforced

AB110-EXT-N Sound Curtains

AB1102-EXT-N2 Sound CurtainsWeatherproof LongTerm Reinforced Soundproofing

AB110EXT-R Sound Curtains

AB110EXT-R2 Sound CurtainsOUTDOOR NOISE CONTROL BLANKETS DATA

AB110-EXT-N SOUND CURTAINS

BBC-EXT-N-2” SOUND CURTAINS

AB110EXT-R SOUND CURTAINS

AB110EXT-R2 SOUND CURTAINSSoundproofing Blanket & Curtain HardwareAcoustical Blanket Track and Hardware systems are designed for the installation of acoustical curtain enclosures & fiberglass acoustic blankets. The track & hardware can be configured for floor, ceiling, suspended, beam and wall mounted systems. Double track systems allow for slide-open access. Our heavy duty structural steel systems are utilized on large enclosures.

Designed for installation of acoustical curtain enclosures

Double track systems allow for easy access

Floor, suspended, ceiling, beam, and wall mounted acoustical systems

Heavy-Duty structural steel systems availableNew York City Transit Authority:

Problem: Construction noise was spilling into adjacent areas.

Solution: NC-BBC-13-2” acoustical panels were specified to surround the entire work site. El Cajun water treatment plant:

Problem: Construction noise was spilling into adjacent areas.Solution: Consulting engineer specified panels to provide a 15 dB(A) reduction in noise levels. 20 dB(A) reduction measured at theSound blanket fences are one of the best options to turn to when construction noise becomes unbearable. The blankets installed have two great effects, sound is minimized and a visual barrier is set up as well.Unwanted sound like from jack hammers, bull dozers, pile drivers, welding equipments, Vacuums and more are blocked with our sound blanket fence. To help mitigate noise for all surrounding the construction site, architects and engineers have started specializing in noise control! Also the OSHA has released documentation on noise and sound control on construction sites. A sound blanket fence is usually installed before excavation; typically a perimeter fence is installed surrounding the construction site for safety our sound blocking blanket can be directly attached to your existing fence, these panels are modular, come with grommets and are as easy to install as they are to remove. This is the most efficient action you may take to prevent complaints of close by neighbors and residents about construction site noise.Applications

- Noise Barrier Outdoor Weatherproof short term Acoustic BlanketNoise Barrier Sound Transmission

- High Temperature Acoustic blankets

- Sound Curtians for Exterior Grade Noise

- Barricade Soundproofing Baffle

- Weatherproof LongTerm Acoustic Blanket

- Sound Curtians for Exterior Grade Noise

- Outdoor Sound Curtain Case Study

Unsure if you found your noise control solution? Call us right away at 407-559-7127 or fill out our contact form here. We look forward to hearing from you!

Call us today at 407-559-7127

Question? Fill out our contact form for more information or a call back!

Acoustic Blanket Non-Reinforced

NC-AB12 Noise Barrier/Sound Absorber Composite

NC-AB13 (1lb 3”) Noise Barrier

NC-AB22 (2lb 2″) Noise Barrier

High Temperature Acoustic Blanket

AB12-HT High Temperature Noise Barrier

Outdoor Soundproofing Weatherproof

AB1-110 Outdoor Short Term Sound Curtains

NC-AB1-112 Outdoor Short Term Sound Curtains

Outdoor Weatherproof Soundproofing

NC AB-220 Acoustic Quilted Fiberglass Absorbtion Blanket

Weatherproof LongTerm Sound Curtains – non-reinforced

AB110-EXT-N Sound Curtains

AB1102-EXT-N2 Sound Curtains

Weatherproof LongTerm Reinforced

AB110EXT-R Sound Curtains

AB110EXT-R2 Sound Curtains

OUTDOOR NOISE CONTROL BLANKETS DATA

AB110-EXT-N SOUND CURTAINS

BBC-EXT-N-2” SOUND CURTAINS

AB110EXT-R SOUND CURTAINS

AB110EXT-R2 SOUND CURTAINS

Outdoor Noise Control Specs:

- Sound Curtians for Exterior Grade Noise

- Sound Blanket or Acoustic Blankets -AB Series Data

- High Temperature Acoustic blankets

- Acoustic Blanket Reinforced Exterior

- Outdoor Weatherproof Acoustic Blanket

- Sound Blanket & Curtain Hardware